![]() 2013-11-05 / 03:42 UTC GMT +00:00

2013-11-05 / 03:42 UTC GMT +00:00

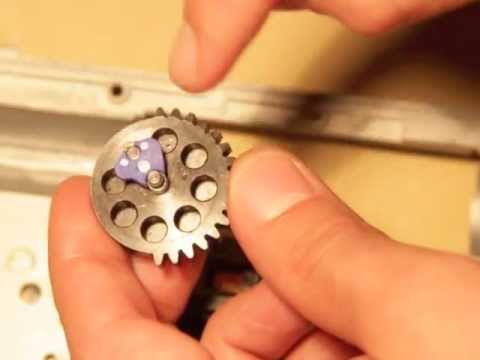

Your airsoft nozzel and tappet plate work in conjunction load bb’s into your barrel and well as create a tight seal between your nozzle and your bucking.

Each version gearbox has a particular length nozzle and slightly different tappet plate. Each version serves the same purpose. If you take a look at the GIF above you can see how a v2 gearbox functions. With each revolution of the sector gear, your tappet plate gets pulled back from a post on the gear itself. Your nozzle gets retracted as well since its connected to the tappet plate. When that happens your nozzle gets retracted on your cylinderhead stem, the spring tension from your magazine will push a bb into your hop up chamber, when that happens your nozzle gets released from its spring tension and the bb gets pushed forward into your bucking. At that exact same moment your piston gets released while your nozzle is in its forward position creating a tight air seal against the bucking and the piston gets released creating a shot.

Nozzles are normally made from metal or plastic. In my opinion it’s not the material that makes a difference it’s whether or not it creates a tight seal against your bucking. For example I have been using the same stock plastic nozzle in my G&G since I purchased it 3 years ago. Some aftermarket nozzles have an o ring seal which creates a tighter seal against your cylinder head stem.

Tappet plates are not normally worth upgrading, either it works or it doesn’t. It’s not a part that normally breaks but it does happen. Replace when needed.

if you have any questions please post them.

Each version gearbox has a particular length nozzle and slightly different tappet plate. Each version serves the same purpose. If you take a look at the GIF above you can see how a v2 gearbox functions. With each revolution of the sector gear, your tappet plate gets pulled back from a post on the gear itself. Your nozzle gets retracted as well since its connected to the tappet plate. When that happens your nozzle gets retracted on your cylinderhead stem, the spring tension from your magazine will push a bb into your hop up chamber, when that happens your nozzle gets released from its spring tension and the bb gets pushed forward into your bucking. At that exact same moment your piston gets released while your nozzle is in its forward position creating a tight air seal against the bucking and the piston gets released creating a shot.

Nozzles are normally made from metal or plastic. In my opinion it’s not the material that makes a difference it’s whether or not it creates a tight seal against your bucking. For example I have been using the same stock plastic nozzle in my G&G since I purchased it 3 years ago. Some aftermarket nozzles have an o ring seal which creates a tighter seal against your cylinder head stem.

Tappet plates are not normally worth upgrading, either it works or it doesn’t. It’s not a part that normally breaks but it does happen. Replace when needed.

if you have any questions please post them.