High speed motor VS high torque.

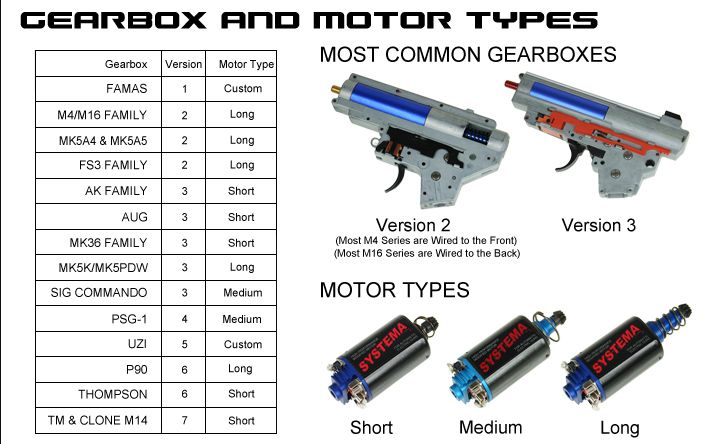

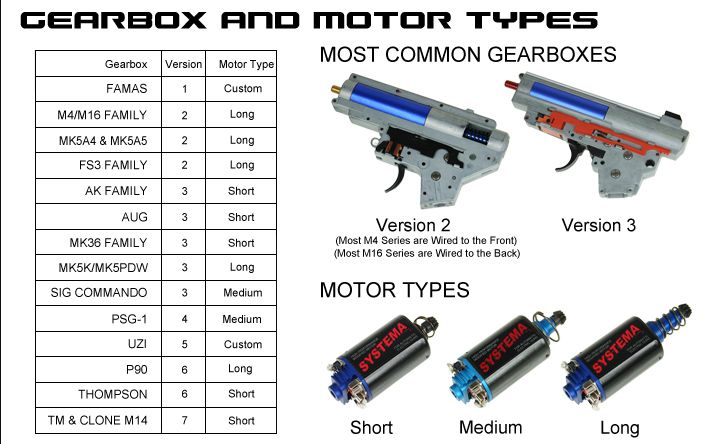

There are a lot of different Airsoft motors on the market right now. Long, medium and short versions are at your disposal depending on what version gearbox you are using it on.

So what makes a motor high speed VS high torque?

It’s all about the magnets inside the motor and how many coils of wire are on the pinion. High speed motors will generally have less powerful magnets and less wire coils which will allow the motor to spool up higher speeds than a motor with stronger magnets. High speed motors are great for giving you an added boost in ROF. High speed motors lack trigger response (the time it takes for your AEG to shoot after the trigger is pulled) because the motor has a longer lag period and takes longer to reach its full spin potential. High speed motors usually recommend you use nothing faster than a 400FPS spring. Anything faster and your motor might not be able to pull back the spring you are using (battery pending).

Some of the better High torque motors that are being produced are being made with Neodymium magnets and much denser wire coils. These super strong magnets are used to help motors pull back the strongest of springs. High torque motors have a much slower top end speed than high speed motors but they will reach top end speed much fastest than a high speed motor will. The benefit to this is fast, snappy trigger response.

Just as a comparison between high torques to high speed motors.

My G&G m4 back in the day has a G&P m120 high speed motor in it. That motor paired up with my 11.1v 15c battery gave me 26 BPS at 400FPS. Trigger response was decent but it was most definitely lacking.

That same AEG with Guarders Infinite torque up motor and the same battery gave me 21 BPS, at 400FPS and lightning fast amazing trigger response.

Personally I’m all about trigger response with my builds and not super fast rate of fire.

Please note that HS/HT motors are not the only way to get fast trigger response/high ROF builds, but is just a fraction of the total build equation.

Like always if you would like to add anything please post away.

Like always if you would like to add anything please post away.

So what makes a motor high speed VS high torque?

It’s all about the magnets inside the motor and how many coils of wire are on the pinion. High speed motors will generally have less powerful magnets and less wire coils which will allow the motor to spool up higher speeds than a motor with stronger magnets. High speed motors are great for giving you an added boost in ROF. High speed motors lack trigger response (the time it takes for your AEG to shoot after the trigger is pulled) because the motor has a longer lag period and takes longer to reach its full spin potential. High speed motors usually recommend you use nothing faster than a 400FPS spring. Anything faster and your motor might not be able to pull back the spring you are using (battery pending).

Some of the better High torque motors that are being produced are being made with Neodymium magnets and much denser wire coils. These super strong magnets are used to help motors pull back the strongest of springs. High torque motors have a much slower top end speed than high speed motors but they will reach top end speed much fastest than a high speed motor will. The benefit to this is fast, snappy trigger response.

Just as a comparison between high torques to high speed motors.

My G&G m4 back in the day has a G&P m120 high speed motor in it. That motor paired up with my 11.1v 15c battery gave me 26 BPS at 400FPS. Trigger response was decent but it was most definitely lacking.

That same AEG with Guarders Infinite torque up motor and the same battery gave me 21 BPS, at 400FPS and lightning fast amazing trigger response.

Personally I’m all about trigger response with my builds and not super fast rate of fire.

Please note that HS/HT motors are not the only way to get fast trigger response/high ROF builds, but is just a fraction of the total build equation.

Like always if you would like to add anything please post away.

Like always if you would like to add anything please post away.